HDD STARTER RODS AND ADAPTERS

HDD Starter Rods /Collars /Sub Savers / Housing Savers & Adapters

Railhead products

HDD Tools and Pipe Components for all Rigs

Railhead housing savers, adapters and transition rods are used to greatly reduce the repair cost. Selecting the proper tooling is crucial to the success of your operation. Railhead offers tooling options for all rig and pipe manufactures on the market. Please help us choose the proper tooling for your application

StraightLine® produced its first directional drill in 1989. Since that time, StraightLine® has manufactured nearly one thousand drills and accumulated many thousands of hours of hands-on drilling experiences. We have drilling experience in every ground condition that creation could throw at us in locations all across North America, Australia, Europe and Asia. Final result, StraightLine® has the industry's most extensive line of HDD tools. At StraightLine® our emphasis on down hole tooling products isn't an afterthought, it is in our DNA.

StraightLine® produced its first directional drill in 1989. Since that time, StraightLine® has manufactured nearly one thousand drills and accumulated many thousands of hours of hands-on drilling experiences. We have drilling experience in every ground condition that creation could throw at us in locations all across North America, Australia, Europe and Asia. Final result, StraightLine® has the industry's most extensive line of HDD tools. At StraightLine® our emphasis on down hole tooling products isn't an afterthought, it is in our DNA.

HDD Mixing Systems

StraightLine - Mix & Storage Tanks

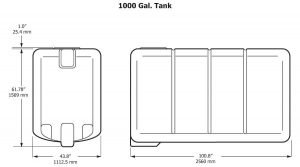

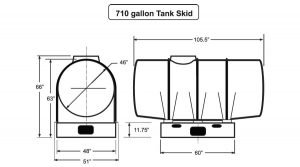

710 & 1,000 Gallon Mix & Storage Tanks

The main features for our mix and storage tanks are:

- Urethane paint on steel components

- 3" (7.6 cm) full port bungs

- Shutoff valves on the suction and discharge ports

- 710-gallon (2,688 L) tanks have a mix circuit with three tank guns to deliver a fast and thorough yield

- 1,000-gallon (3,785 L) tanks have a mix circuit with four tank guns to deliver a fast and thorough yield

Performix Mixing Systems

Our Performix® family of mixers delivers unmatched shearing, mixing and yield.

Bentonite is introduced to the system through a large diameter port, where it immediately encounters a high-speed jet stream. This high-speed stream is extremely effective at shearing and separating the bentonite plates, which dramatically speeds the yielding process.

- The result: maximum yield in shortest time.

- The benefit: less time mixing, more time drilling.

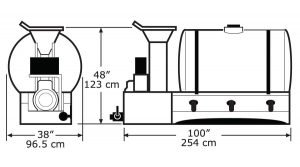

Performix® SL300 Self-contained 300 Gallon Mixing Solution

The SL300 is a complete, self-contained 300-gallon mixing solution ready to bolt to your truck or trailer and go to work. Its compact footprint makes it an ideal solution where space is at a premium.

The main features for the SL300 are:

- Tank Capacity: 300 gallons

- Engine: Kohler® Command CS Pro 6 Hp (4.5 Kw) engine

- Pump: 170-gpm (11 lps) designed to turn tank over in less than 2 minutes

- Fuel Tank: 6-gallon (23 L) fuel tank for extended run time between refueling

- Hopper: Large capacity with pivoting lid that doubles as a bag rest

- Jet: High-speed jet effectively shears the bentonite plates, thereby producing the highest possible yield

- Tank Guns: 3 tank guns intensify tank roll for rapid shearing and yielding

- Connections: 2" (5.1 cm) suction and discharge ports w/ball valves

- Mounting: Adapts easily to any trailer

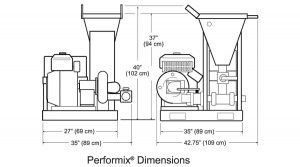

Performix® Mixer

The Performix® Mixer with its 365-gpm output will get you from bentonite introduction to fully sheared, yielded and ready to drill in a matter of minutes. The Performix is the ideal match for our 700-gallon (2650-liter) tanks.

The main features for the Performix Mixer are:

- Engine: Kohler® Command CS Pro 12 Hp (9 Kw) gas engine w/heavy duty cyclonic air cleaner and electric start

- Pump: 365 (23 lps) gpm designed to turn tank over in less than 2 minutes

- Fuel Tank: 6-gallon (23 L) fuel tank for extended run time between refueling

- Hopper: Large capacity with pivoting lid that doubles as a bag rest

- Jet: High-speed jet effectively shears the bentonite plates, thereby producing the highest possible yield

- Mechanical Seal: Runs in antifreeze so seal is constantly lubricated (the pump can be run dry without damaging the seal)

- Connections: 3" (7.6 cm) camlock on suction side, 3" (7.6 cm) hose barb on discharge side and a 2" (5.1 cm) male cam-lock for supply hose

- Mounting: Adapts easily to any truck or trailer

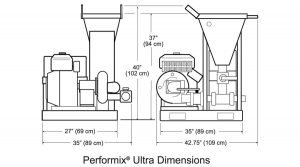

Performi® Ultra Mixer

The Performix® Ultra Mix System with its 450-gpm output will get you from bentonite introduction to fully sheared, yielded and ready to drill in a matter of minutes. The Performix Ultra is ideally suited for our 1,000-gallon (3,800-liter) tank skid.

The main features for the Performix Ultra Mix System are:

- Engine: Kohler® 20 Hp (15 Kw) gas engine w/electric start

- Pump: 450-gpm (28 lps) designed to turn tank over in about 2 minutes

- Fuel Tank: 6-gallon (23 L) fuel tank for extended run time between refueling

- Hopper: Large capacity with pivoting lid that doubles as a bag rest

- Jet: High-speed jet effectively shears the bentonite plates, thereby producing the highest possible yield

- Mechanical Seal: Runs in antifreeze so seal is constantly lubricated (the pump can be run dry without damaging the seal)

- Connections: 3" (7.6 cm) camlock on suction side, 3" (7.6 cm) hose barb on discharge side and a 2" (5.1 cm) male cam-lock for supply hose

- Mounting: Adapts easily to any truck or trailer

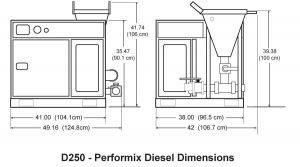

Performix® Diesel Mixer

The Performix® Diesel Mixer with its 450-gpm output will get you from bentonite introduction to fully sheared, yielded and ready to drill in a matter of minutes. The Performix Ultra is ideally suited for our 1,000-gallon (3,800-liter) tank skid.

The main features for the Performix Diesel Mixer are:

- Engine: Lombardini 25HP diesel engine w/electric start

- Pump: 450-gpm (28 lps) designed to turn tank over in about 2 minutes

- Fuel Tank: 6-gallon (23 L) fuel tank for extended run time between refueling

- Hopper: Large capacity with pivoting lid that doubles as a bag rest

- Jet: High-speed jet effectively shears the bentonite plates, thereby producing the highest possible yield

- Mechanical Seal: Runs in antifreeze so seal is constantly lubricated (the pump can be run dry without damaging the seal)

- Connections: 3" (7.6 cm) camlock on suction side, 3" (7.6 cm) hose barb on discharge side and a 2" (5.1 cm) male cam-lock for supply hose

- Mounting: Adapts easily to any truck or trailer

Surface to Surface Mixers

STS Mixers are the top performers for the right mix, every time. With the widest selection of options available, you can get the right fit for your project or work environment.

STS Mixers are guaranteed to perform the way we say they will, or you can return the mixer for a full refund. We’re proud to say that out of the hundreds of mixers sold, not one has been returned.

Take a look at the range of sizes and options, and if you don’t find exactly what you need, contact us for a discussion about your custom requirements.

M-Series Mixers (Portable and Independent)

The M series universal mixers are designed with the same attention to detail our customers have come to trust from the time-proven M series mixers from STS. Powered by your choice of power options and driving a 2, 3 or 4-inch centrifugal pump, it makes effective use of the patented 4-point mixing system. The M series of mixers can be used as a new installation or retrofitted into an existing system.

Since the unit can be connected by hoses or hard piping, the placement of the mixer versus the tank(s) is less restricted and a configuration to suit the available space and the contractor's needs is easier to achieve. The small size also allows it to be used as a portable, independent unit that can be transported separately from site to site.

With dimensions ranging from as small as 33" long x 38" wide and 300 lbs (M2) to 62" long x 46" wide and 1250 lbs (M4), and with the choice of four power options, you should be able to choose a unit to suit your needs.

Click on each model below to learn more:

M-300 Mixers (SAM Juniors)

The M-300 was the original Sam-Series Mixer, designed and manufactured primarily for smaller size drill rigs as an alternative to using plain water. A 3" centrifugal pump makes effective use of the patented STS mixing system. This mixing unit can provide 300 gallons of yielded fluid for your drill rig in less than five minutes. The compact unit can be transported to the job site in a standard 8' pickup box.

M-750 Mixers (SAM Seniors)

The M-750, with its rectangular loaf-shaped Roto-Mold tank, is a space saving design with an almost square footprint. With a 4-inch centrifugal pump, this unit makes effective use of the patented STS mixing system and is capable of providing 750 gallons of yielded fluid to your drill rig in less than eight minutes. Added benefits include the ability to draw water from a second tank and send mud to your drilling rig or storage tank without the use of a second pump. It is lightweight for easy transport and fits any 8' flat deck.

M-1500 Mixers (Dual Tank Series)

The M-1500 is a dual-tank system that allows two methods of mixing: you can mix 750 gallons of yielded fluid in less than eight minutes, while holding 750 gallons of water reserve in the second tank for the next mix; or mix one large batch of 1500 gallons of full yield in less than 16 minutes. The operator controls the two methods of mixing by changing the direction of flows through the piping connections using the manually-operated full flow valves. The vacuum port located in the mixing tee has the ability to draw water from the second tank when being used as a reservoir, and the drill fluid can then be sent to your drilling rig without the use of a second pump. This model has been a popular choice for HDD contactors due to its small space-saving footprint relative to its capacity.

HDD Air Hammers

StraightLine

Double your production rate with the industry's hardest-hitting air hammer.

At home in a variety of rock and soil conditions, StraightLine® Steerable Air Hammer Systems are designed to turn any rig into a rock-drilling machine, capable of drilling at rates up to 150 feet per hour.

Three key design features drive our hammer systems' performance:

Powerful

The StraightLine® hammers incorporate a heavy-duty outer body, which allows for a larger, harder-hitting piston. For example, the AH5.0's 30-pound piston is nearly 2x heavier than competitive hammers. Its simple physics: a heavier piston delivers more percussive force per blow to the bit face which translates into faster penetration rates.

Durable

StraightLine® has taken durability to a whole new level, extending component life up to 10x, driving operating costs down and profits up. It's no secret, we have simply fitted our ground engaging components with strategically placed raised carbides that provide serious gage protection. You can think of it as body armor. For example, our AH5.0 sports 78 raised carbide buttons encasing the bent sub and running the entire length of the transmitter housing.

Steerable

The StraightLine® Air Hammer System combines powerful hammering action with our precise two-point steering system to successfully navigate a wide variety of ground conditions. No matter whether you are faced with solid hard-rock formations, soft rock formations or intermittent conditions such as boulders separated by soil, our Air Hammer Systems’ will hit your target.

Additional Benefits: Unmatched ROI & Environmental Friendliness

Unmatched ROI: turns your existing drill into a rock drill; low capital investment; low cost per foot of operation, production rates up to 150' per hour; bottom line, no other method can match the cost/performance ratio of the StraightLine® Hammer System.

Environmentally Friendly: the StraightLine® Air Hammer Systems really shine when environmentally sensitive jobsites are encountered. Only 1/2 to 5-gpm of fluids are required for transmitter cooling, hammer lubrication and hole cleaning leaving the jobsite virtually spotless.